wire edm machine how it works

Also the cutting tool applies the force to remove the material from the work-piece during machining. This form of machining can cut any material that will conduct electricity whether it is a hard or soft material.

Taper Angles And Wire Edm Moldmaking Technology

We use 4-axis wire EDM to make tools used to wrap a coating around an object.

. Wire EDM also known as WEDM in the wire EDM process a thin single-strand wire works as the electrode and the wire are continuously fed from the automatic feed with the spool during the process the electrical discharge is created between the wire and workpiece as the spark moves across the gap the material is then removed from. Basic introduction to the wire EDM and high-speed small hole EDM processes. Ad Full suite of CNC machining services including the latest in wire EDM machining.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. Unlike other types of machining wire EDM exerts no cutting force on the workpiece and introduces no residual stress. In the early days it was difficult to manufacture parts with fine shapes and tight tolerances using conventional machining techniques but nowadays parts with tight tolerances can be achieved by the electric discharge cutting process using wire cutting.

EDM is an abbreviation for Electrical Discharge Machining. No actual contact is made between the wire and the material which prevents distorting the path of the wire or damaging the part. It Doesnt Need Mechanical Force.

In addition to extrusion tools here are some of the other parts we commonly make using this capability. An electrical discharge spark is created between two electrodes solid electric conductors. There are three types of EDM.

The use of precisely focused electrical discharges makes it possible to make complex or intricate shapes and patterns. How It Works. Wire EDM machines can make different shapes such as contours and holes even on the hardest and the most fragile materials.

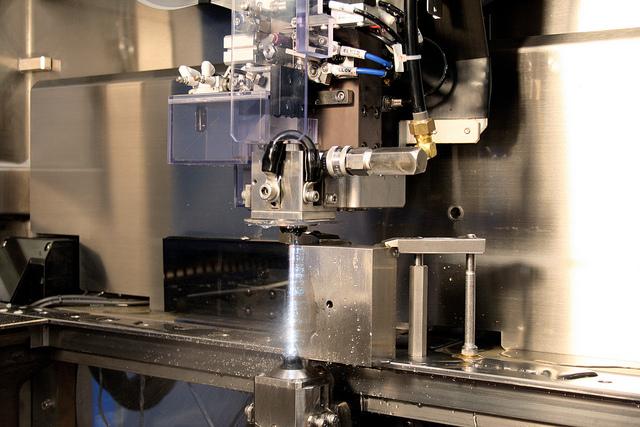

To begin the cut the wire must cut into the metal from the side or through a hole that is drilled into the center of the metal. A lot of the time the wire EDM CNC mill will be instructed by an operator who is a person who is experienced with CNC machines. For quality parts delivered on time choose Xometry cnc machining services.

EDM is an abbreviation for Electrical Discharge Machining. Generally the more powerful machines require more space and cost more to operate. There is little or no change in the mechanical properties.

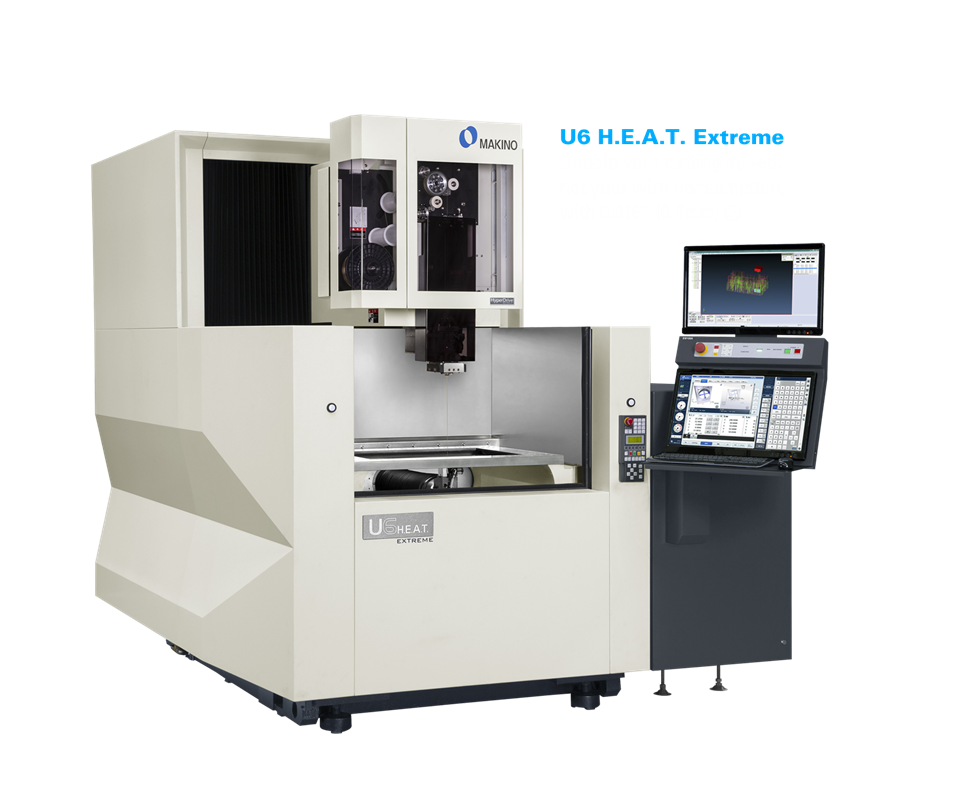

The cutting wire is stretched tight. A wire EDM machine uses a thin piece of electrically charged wire as a saw blade to cut any metal which will conduct electricity. A new machine and its associated servicing.

The upside of using a larger wire cutting machine is that it can work on larger and smaller workpieces. An arbor the electrode holder and the dielectric fluid. Wire EDM uses a thin wire composed of copper or brass to conduct electrical current between an electrical source and an electrically conductive base material.

A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts. For example a. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always harder than the work-piece.

The wire electrode is consumed during the. EDM stands for electric discharge machining. They will then instruct the machine to go ahead and perform the cut.

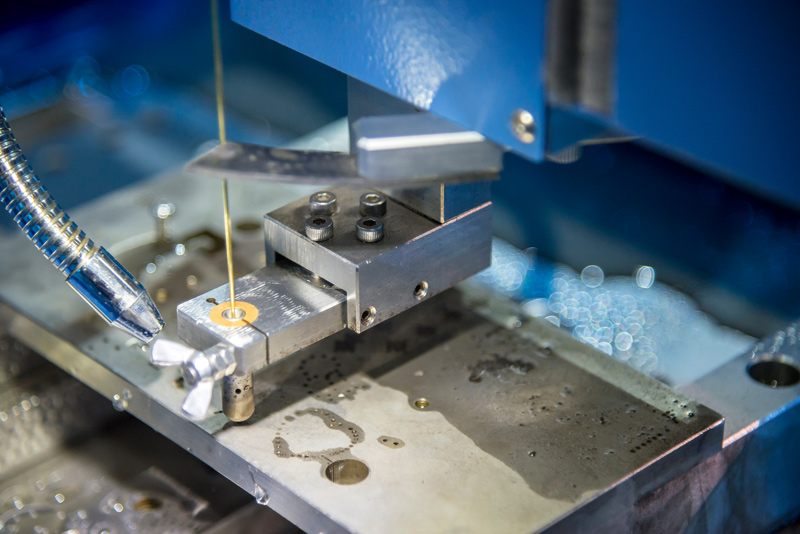

The EDM wire is tinymeasuring only 0010 to 0012and it may be made of brass or other materials for specific applications. The current creates sparks capable of cutting the substrate into pre-programmed designs. Types of Electrical Discharge Machining.

As the spark jumps across the gap materia. The Five Benefits of Using a Wire EDM. Wire EDM machining also known as spark EDM works by creating an electrical discharge between the wire or electrode the workpiece.

How Electrical Discharge Machining Works. The wire electrode in your EDM-wire cut machine is used only once since the wire becomes weak after spark discharge. An edm machine contains three main components.

The arbor is the drive shaft of the machine which rotates at high speeds in order to force metal into the cutting area. A simplified overview of the process. It shoots tiny lightning bolts through a water or oil insulator called a dielectric using electrical energy to blast away tiny bits of metal.

What Is EDM Machining EDM is a machining process that uses electrical currents to cut metal. Your EDM-wire cut machine cuts the material by continuous spark discharges between the moving wire and the work-piece surface. The wire is energized as it passes across a.

Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material. A wire EDM machine looks like a bandsaw that has a wire for a blade. This method allows us to achieve the tapered effect and the small.

The water helps cool the material being cut and also helps wash away metal as it is freed. Wire EDM also known as wire electrical discharge machining WEDM or wire-cut EDM involves using a thin single-strand metal conductive wire like brass along with de-ionized water allows the wire to cut through metal with the heat from electrical sparks. One of the first things to consider when looking at an EDM wire machine is the space requirement.

4-axis wire EDM is an efficient way to create complex parts with high precision. The sparks happen in a square waveform and the spark-on and spark-off time is controlled by the CNC. The material is submerged in deionized water to prevent overheating or warping facilitating.

Wire EDM is a form of machining which is done using a thin wire that can cut in any XYUV direction. Wire EDM machines can be rotated on these axes to create tapered indentations. What makes this special is that it can cut without contact and produces a.

Short interesting video on the fundamentals of the electrical discharge machinin. The basic electrical discharge machining process is really quite simple. The Electrical Discharge Machining EDM is an unconventional.

Sinker EDM Wire EDM and Fast hole drilling EDM. The spark takes place in deionized water. When you are working with a wire EDM CNC machine it is important to remember that it does require a high level of skill and attention to detail.

A wire EDM unit can be programmed to cut complex shapes small or large to a dimensional tolerance of 00001 inch and can be trusted to do so repeatedly and reliably. A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts. Simply put you can think of wire EDM as a highly accurate bandsaw one with a blade wire measuring 0010 or so in diameter.

The term EDM stands for Electrical Discharge Machining. The dielectric fluid acts as a insulator between the electrodes and.

Punch Tools Edm Wire Edm Edm Wire Cutting Edm Extrusion Wire Erosion Edm Wire Burning Wire Edm Vancouver Electrical Discharge Machining

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

How It Works Wire Edm Today S Machining World

How Wire Edm Works Missouri S Wire Edm Machine Shop

What Is Wire Edm Electrical Discharge Machining Xact

Cnc Wire Cut Edm Basic Operation Youtube

What Is Wire Edm Process Benefits Applications

How Does Wire Edm Work Laszeray Technology Llc

Wire Edm Machining Cutting Services Moon Tool

How Does Wire Cutting Work Dienamics

How It Works Wire Edm Today S Machining World

What Is Wire Edm A Guide To Wire Electrical Discharge Machining

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube